Metals

Metals are a group of chemical elements characterized by metallic bonding and electron delocalization. In this structure, atoms share their outer electrons across a crystal lattice, forming a stable "electron sea." This phenomenon results in high electrical and thermal conductivity, malleability, ductility, and remarkable mechanical strength — properties that form the foundation for their applications in heavy industry, energy, automotive, infrastructure, and advanced material production.

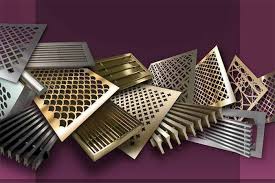

Classification of Metal Products

- Iron Ore Concentrate

Iron ore concentrate is produced through processes that enrich and separate iron-bearing minerals from waste materials. With a high iron content and minimal impurities, this product serves as the primary feedstock for pellet production and direct reduced iron (DRI). Precise control of particle size distribution, moisture content, and chemical composition is critical to the efficiency of reduction furnaces and the production of high-quality steel.

- Direct Reduced Iron (DRI)

Direct Reduced Iron is a strategic product in the modern steelmaking chain, obtained by the direct reduction of iron ore using reducing gases (CO and H₂). The resulting product features high purity and a porous structure, enabling rapid melting and precise control over chemical composition. As the steel industry transitions toward low-carbon technologies, the use of hydrogen in DRI processes has become increasingly significant.

- Iron Ore Pellets

Pellets are produced by combining iron ore concentrate with additives and binders, followed by thermal agglomeration. Their uniform size, high mechanical strength, and controlled chemical composition make them ideal feedstock for direct reduction furnaces and blast furnaces. Advanced pelletizing technologies enhance operational efficiency while reducing environmental emissions.

- Aluminium Alloys

Aluminium alloys are formulated by adding alloying elements such as silicon, magnesium, copper, and zinc, achieving an optimal balance of lightweight, high strength, and corrosion resistance. These characteristics make aluminium alloys essential in aerospace, automotive, and packaging industries. Recent research focuses on microstructure refinement, enhanced thermal resistance, and extended fatigue life.

- Copper Alloys

Copper alloys, containing elements such as tin, aluminium, nickel, and zinc, provide an optimized set of properties including high electrical conductivity, corrosion resistance, and mechanical strength. They are widely applied in electrical components, marine equipment, and thermal systems. Current studies emphasize maintaining conductivity while enhancing strength through crystal structure modification.

- Copper Isotopic Alloys

Copper isotopic alloys are engineering materials in which the isotopic composition of copper is precisely controlled to optimize thermal stability, uniform conductivity, and oxidation resistance. These alloys are increasingly used in precision electronics, heat transfer systems, semiconductor manufacturing, and vacuum technologies. Products are typically supplied as high-purity ingots or engineered components, fully compliant with international standards.

- Pig Iron / Ingots

Pig iron is an intermediate product obtained by smelting iron ore in a blast furnace, containing carefully controlled amounts of carbon and alloying elements. It serves as the primary raw material for steel and cast iron production. Precise control over chemical composition, shape, and weight ensures consistent quality across the steel production and export supply chain.

Mazdaco Trading & Export Company

With extensive experience in international trade, Mazdaco Trading & Export Company is recognized as a prominent supplier of metals and industrial materials. Leveraging a comprehensive supply network, rigorous quality control processes, and professional logistics services, we have secured a distinctive position in global markets.

Products and Services

We offer a broad range of metal products, including:

- Iron Ore Concentrate: High iron content with minimal impurities, ideal for pellet production and direct reduced iron (DRI).

- Direct Reduced Iron (DRI): High-purity, porous iron, perfectly suited for direct reduction furnaces.

- Iron Ore Pellets: Uniform particle size and high mechanical strength, suitable for direct reduction furnaces and blast furnaces.

- Aluminium and Copper Alloys: Precisely formulated with alloying elements for specific applications across various industries.

- Pig Iron: Controlled chemical composition, appropriate for steel and cast iron production.

In addition, we provide a range of professional services, including:

- Technical Consulting: Delivering tailored engineering and economic solutions to meet the unique needs of our clients.

- Logistics Services: Managing transportation and customs clearance efficiently through our global logistics network.

- Risk Management: Offering financial tools to mitigate price fluctuations in international markets.

Standards and Certifications

Our company guarantees the quality of its products and services by adhering to international standards such as ISO 9001 and ISO 14001. Furthermore, through collaborations with globally accredited laboratories like SGS and Bureau Veritas, we ensure that our products meet the highest international quality standards before reaching clients.

Supply Network and Logistics

Through partnerships with trusted suppliers in Iran, the UAE, and other regional markets, we have established a robust global supply network. This network enables us to provide high-quality products at competitive prices to customers worldwide.

In logistics, we collaborate with reliable international transport companies to deliver fast, secure, and efficient shipping services, including sea, air, and land transport, customs clearance, and complete export/import documentation.

Social Responsibility and Sustainability

Our company is committed to social responsibility and environmental sustainability. By implementing initiatives in energy efficiency, waste management, and the use of renewable resources, we strive to minimize the environmental impact of our operations.

Future Vision

We aim to expand our presence in global markets and offer innovative products and services. By continuously developing and improving our processes with advanced technologies, we ensure that our clients’ needs are met in the most efficient, reliable, and professional manner.

With our experience, expertise, and dedication to quality and customer satisfaction, partnering with Mazdaco provides a valuable opportunity for business growth and development. We are ready to support you with high-quality products and professional services to achieve your commercial goals.